Mọ́tò ìdènà bọ́ọ̀lù aláwọ̀ ara Nema 17 (42mm) 1.8° Fóltéèjì Ìgun Ìgbésẹ̀ 2.1 / 3.7V Wáyà Ìdarí 1A, 4

Mọ́tò ìdènà bọ́ọ̀lù aláwọ̀ ara Nema 17 (42mm) 1.8° Fóltéèjì Ìgun Ìgbésẹ̀ 2.1 / 3.7V Wáyà Ìdarí 1A, 4

Mọ́tò stepper àdàpọ̀ Nema 17 (42mm), bipolar, 4-lead, ball skru, ariwo kékeré, ìgbésí ayé gígùn, iṣẹ́ gíga, CE àti RoHS ni a fọwọ́ sí.

Àpèjúwe

| Orukọ Ọja | 42mm arabara rogodo dabaru stepper motor |

| Àwòṣe | VSM42BSHSM |

| Irú | awọn mọto stepper arabara |

| Igun Igbesẹ | 1.8° |

| Fólítì (V) | 2.6 / 3.3 / 2 / 2.5 |

| Lọ́wọ́lọ́wọ́ (A) | 1.5 / 2.5 |

| Agbára ìdènà (Ohms) | 1.8 / 2.2 / 0.8 / 1 |

| Ìfàsímọ́lẹ̀ (mH) | 2.6 / 4.6 / 1.8 / 2.8 |

| Àwọn Wáyà Ìdarí | 4 |

| Gígùn Mọ́tò (mm) | 34 / 40 / 48 / 60 |

| Iwọn otutu ayika | -20℃ ~ +50℃ |

| Gíga Ìwọ̀n Oòrùn | 80K Púpọ̀ jùlọ. |

| Agbára Dielectric | 1mA Púpọ̀ Jùlọ @ 500V, 1KHz, 1Sec. |

| Agbára Ìdènà Ìbòmọ́lẹ̀ | 100MΩ Min. @500Vdc |

Àwọn ìwé-ẹ̀rí

Awọn Ilana Itanna:

| Iwọn Mọto | Fọ́ltéèjì /Ìpele (V) | Lọ́wọ́lọ́wọ́ /Ìpele (A) | Àtakò /Ìpele (Ω) | Ìdánilẹ́kọ̀ọ́ /Ìpele (mH) | Iye àwọn Àwọn Wáyà Ìdarí | Ilọkuro Rotor (g.cm)2) | Ìwúwo Mọ́tò (g) | Gígùn Mọ́tò L (mm) |

| 42 | 2.6 | 1.5 | 1.8 | 2.6 | 4 | 35 | 250 | 34 |

| 42 | 3.3 | 1.5 | 2.2 | 4.6 | 4 | 55 | 290 | 40 |

| 42 | 2 | 2.5 | 0.8 | 1.8 | 4 | 70 | 385 | 48 |

| Iwọn Mọto | Fọ́ltéèjì /Ìpele (V) | Lọ́wọ́lọ́wọ́ /Ìpele (A) | Àtakò /Ìpele (Ω) | Ìdánilẹ́kọ̀ọ́ /Ìpele (mH) | Iye àwọn Àwọn Wáyà Ìdarí | Ilọkuro Rotor (g.cm)2) | Ìwúwo Mọ́tò (g) | Gígùn Mọ́tò L (mm) |

| 42 | 2.6 | 1.5 | 1.8 | 2.6 | 4 | 35 | 250 | 34 |

| 42 | 3.3 | 1.5 | 2.2 | 4.6 | 4 | 55 | 290 | 40 |

| 42 | 2 | 2.5 | 0.8 | 1.8 | 4 | 70 | 385 | 48 |

| 42 | 2.5 | 2.5 | 1 | 2.8 | 4 | 105 | 450 | 60 |

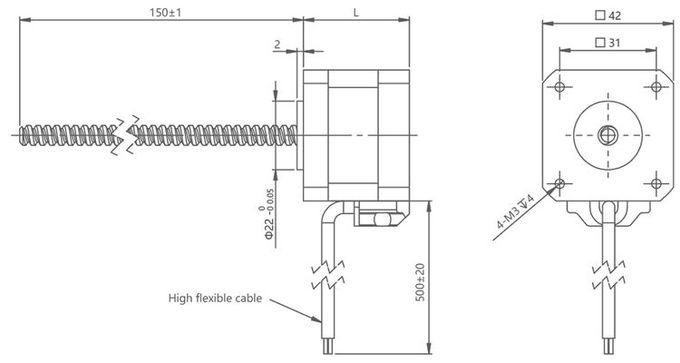

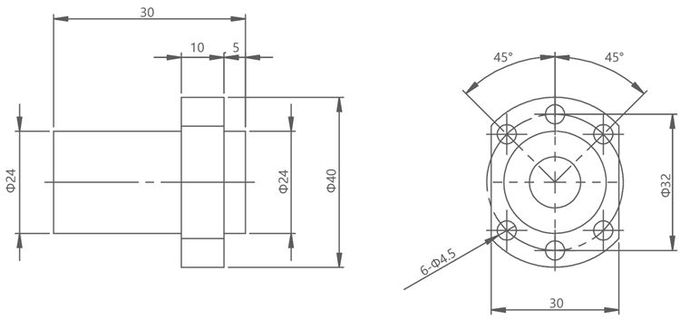

Àwòrán ìṣàfihàn mọ́tò ìta ìta VSM42BSHSM:

Àwọn Àkíyèsí:

A le ṣe adani ipari dabaru asiwaju

Iṣiṣẹ adani jẹ ṣeeṣe ni opin dabaru asiwaju

Jọwọ kan si wa fun awọn alaye diẹ sii ti skru rogodo.

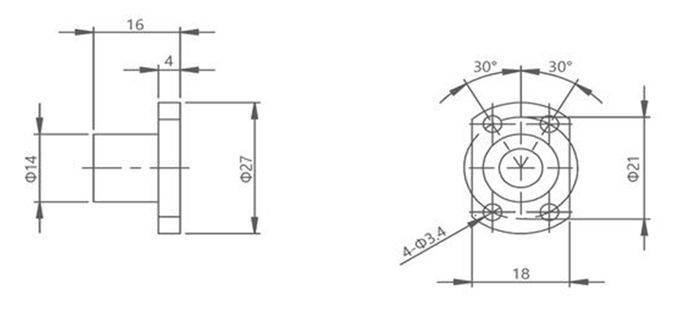

Àwòrán àkójọ VSM42BSHSMBall nut 0801 tàbí 0802

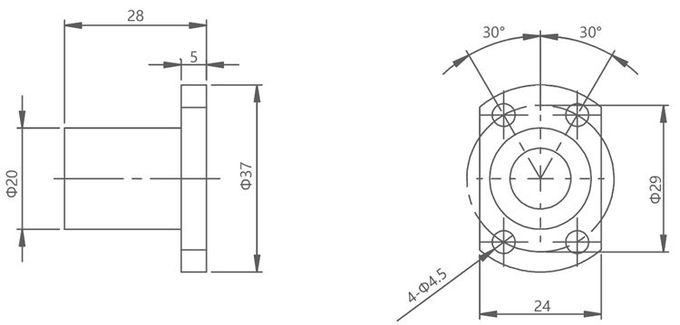

Àwòrán àkójọ VSM42BSHSMBall nut 1202:

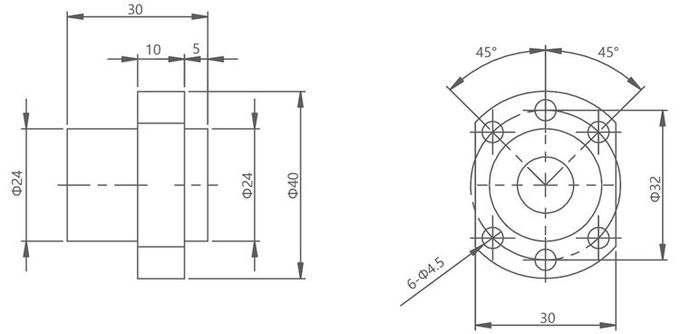

Àwòrán ìṣàfihàn VSM42BSHSMBall nut 1205:

Àwòrán àkójọ VSM42BSHSMBall nut 1210:

Iyara ati titẹ titẹ

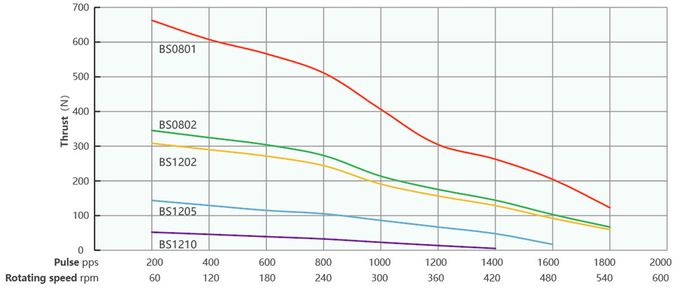

Ìwakọ̀ Chopper Chopper onípele 42 jara 34mm gígùn mọ́tò

Ìgbohùngbà ìṣàn lọ́wọ́lọ́wọ́ àti ìtẹ̀sí ìtẹ̀sí 100%

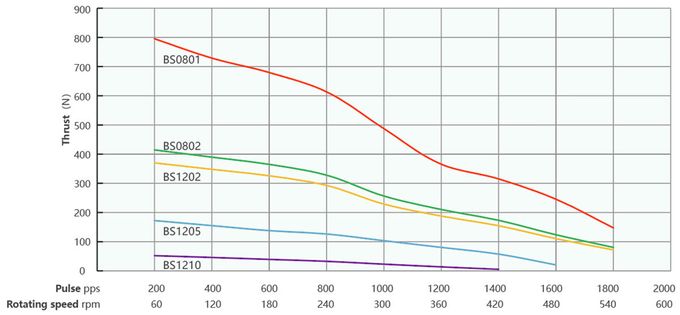

Ìwakọ̀ Chopper Chopper onígun mẹ́rinlélógójì 40mm fún gígùn mọ́tò

Ìgbohùngbà ìṣàn lọ́wọ́lọ́wọ́ àti ìtẹ̀sí ìtẹ̀sí 100%

| Ìdarí (mm) | Iyara onigun (mm/s) | |||||||||

| 1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 2 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| 5 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

| 10 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

Ipo idanwo:Awakọ Chopper, ko si ramp, idaji micro-stepping, folti awakọ 40V

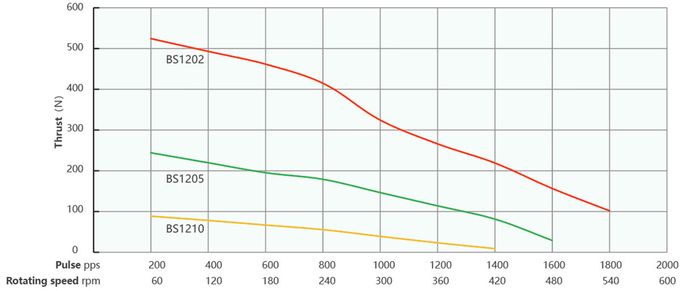

Ìwakọ̀ Chopper Chopper onígun mẹ́rinlélógójì 48mm fún gígùn mọ́tò

Ìgbohùngbà ìṣàn lọ́wọ́lọ́wọ́ àti ìtẹ̀sí ìtẹ̀sí 100%

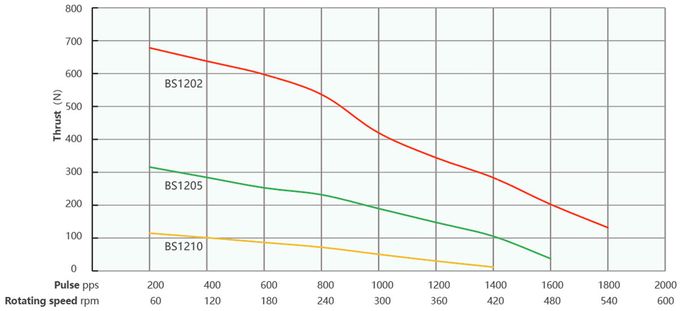

Ìwakọ̀ Chopper Chopper onígun mẹ́rìnlélógójì 60mm fún gígùn mọ́tò

Ìgbohùngbà ìṣàn lọ́wọ́lọ́wọ́ àti ìtẹ̀sí ìtẹ̀sí 100%

| Ìdarí (mm) | Iyara onigun (mm/s) | |||||||||

| 1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 2 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| 5 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

| 10 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

Ipo idanwo:Awakọ Chopper, ko si ramp, idaji micro-stepping, folti awakọ 40V

Awọn agbegbe ti a lo:

Awọn ohun elo adaṣiṣẹ:A le lo awọn mọto wọnyi ninu ọpọlọpọ awọn ohun elo adaṣe gẹgẹbi awọn laini apejọ adaṣe, ẹrọ iṣakojọpọ, awọn eto ipamọ adaṣe, ati bẹbẹ lọ. Wọn pese ipo deedee giga ati iṣakoso išipopada ti o gbẹkẹle fun ifọwọyi deede ati ipo awọn iṣẹ.

Àwọn ẹ̀rọ ìtẹ̀wé 3D:A le lo awọn mọto stepper ball skru 42 mm ninu awọn aake gbigbe ti awọn ẹrọ itẹwe 3D fun ipo deede ati iṣakoso išipopada ti ori titẹ. Pẹlu iṣakoso ipo deede, awọn abajade titẹjade didara giga ni a le ṣaṣeyọri.

Awọn irinṣẹ ẹrọ CNC:A le lo awọn mọto wọnyi ninu awọn aake išipopada ti awọn irinṣẹ ẹrọ CNC gẹgẹbi awọn tabili ipo XYZ, awọn ẹrọ milling, ati awọn ẹrọ fifin. Wọn pese deede giga, iṣelọpọ iyipo giga ati iṣakoso išipopada ti o gbẹkẹle fun ẹrọ ṣiṣe deede ati fifin.

Ohun elo Iṣoogun:A le lo awọn mọto stepper ball skru 42mm ninu awọn ohun elo iṣoogun gẹgẹbi awọn ohun elo aworan iṣoogun, awọn roboti iṣẹ-abẹ, ati awọn ohun elo iṣoogun adaṣiṣẹ. Wọn pese iṣakoso ipo ti o peye ati išipopada iduroṣinṣin fun ifọwọyi daradara ati adaṣiṣẹ ti awọn ilana iṣoogun.

Awọn Ẹrọ Aṣọ:A le lo awọn mọto wọnyi fun oniruuru awọn aake ti išipopada ninu awọn ẹrọ aṣọ, gẹgẹbi awọn aṣọ wiwun, awọn ẹrọ wiwun, awọn ẹrọ iṣẹ-ọnà, ati bẹbẹ lọ. Wọn mu ki awọn iṣipopada iyara giga ati deede gaan fun iṣelọpọ ati sisẹ awọn aṣọ.

Rọ́bọ́ọ̀tìkì:Àwọn mọ́tò ìdènà bọ́ọ̀lù aláwọ̀ 42 mm ni a ń lò nínú àwọn ìsopọ̀ àti àwọn actuators nínú àwọn robot. Wọ́n ń pèsè ìṣàkóso ipò pàtó àti ìyọrísí agbára gíga, a sì ń lò wọ́n láti ṣe ìṣípo àti ìṣiṣẹ́ àwọn robot tó péye.

Àǹfààní

Iṣedeede Ipo Giga:Àwọn mọ́tò ìdènà bọ́ọ̀lù aláwọ̀ 42mm máa ń fúnni ní ìpele tó péye. Ètò ìgbéjáde ìdènà bọ́ọ̀lù náà máa ń dín ìfàsẹ́yìn kù, èyí sì máa ń mú kí ó túbọ̀ péye sí i àti pé ó lè tún un ṣe. Èyí á jẹ́ kí mọ́tò náà dé ibi tó yẹ kí ó sì máa tọ́jú rẹ̀ dáadáa, èyí tó ṣe pàtàkì nínú àwọn ohun èlò tó nílò ipò tó péye.

Àfikún Ìjáde Ìyípadà Ìyípadà:Àwọn mọ́tò wọ̀nyí ń mú kí agbára ìṣiṣẹ́ pọ̀ sí i ní ìfiwéra pẹ̀lú àwọn mọ́tò stepper boṣewa. Ẹ̀rọ ìdènà bọ́ọ̀lù náà yí ìṣípo yíyípo mọ́tò náà padà sí ìṣípo onílànà, èyí tí ó ń yọrí sí ìṣípo yíyípo yíyípo yíyípo padà. Èyí ń jẹ́ kí mọ́tò náà lè wakọ àwọn ẹrù ńlá tàbí kí ó borí agbára ìdènà gíga, èyí tí ó mú kí ó dára fún àwọn ohun èlò tí ó ní àwọn ìbéèrè agbára ìṣiṣẹ́ tí ó le koko.

Agbara Gbigbe Ti o Dara si:Ètò ìgbéjáde skru bọ́ọ̀lù nínú àwọn mọ́tò wọ̀nyí ń fúnni ní agbára gbígbé ẹrù tí ó dára síi. Apẹẹrẹ náà ń pín ẹrù náà káàkiri gígùn skru náà, èyí tí ó ń jẹ́ kí mọ́tò náà lè gbé ẹrù tí ó ga jù àti kí ó dúró ṣinṣin nígbà tí ó bá ń ṣiṣẹ́. Èyí mú kí wọ́n dára fún àwọn ohun èlò tí ó ní í ṣe pẹ̀lú gbígbé ẹrù tí ó wúwo tàbí ṣíṣiṣẹ́ ní àwọn àyíká tí ó le koko.

Ẹ̀yìn ẹ̀yìn tí ó dínkù:Backlash tọ́ka sí ìṣeré tàbí ìdènà láàárín skru àti nut nínú ètò ìgbékalẹ̀. Ọ̀nà ìdènà bọ́ọ̀lù tí a lò nínú àwọn mọ́tò wọ̀nyí ń ran lọ́wọ́ láti dín ìdènà kù, èyí tí ó ń yọrí sí ìṣàkóṣo ìṣípo àti ìṣedéédéé ìdúró. Ìdínkù ìdènà rírí dájú pé mọ́tò náà ń dáhùn sí àwọn àmì ìṣàkóso ní pàtó, èyí tí ó mú kí ó yẹ fún àwọn ohun èlò tí ó nílò ìṣàkóso tí ó lágbára lórí ìṣípo.

Ṣiṣe ṣiṣe giga:Àwọn mọ́tò ìdènà bọ́ọ̀lù aláwọ̀pọ̀ máa ń ṣiṣẹ́ dáadáa ju àwọn mọ́tò ìdènà bọ́ọ̀lù aláwọ̀pọ̀ lọ. Ètò ìgbéjáde ìdènà bọ́ọ̀lù máa ń dín ìfọ́síwájú kù, èyí sì máa ń mú kí agbára yípadà sí i, ó sì máa ń dín ìpàdánù agbára kù. Èyí túmọ̀ sí pé agbára lílo rẹ̀ dára sí i, ó sì máa ń dín agbára lílo kù, èyí sì máa ń mú kí wọ́n jẹ́ èyí tó rọrùn jù, tí ó sì tún máa ń jẹ́ kí wọ́n jẹ́ èyí tó rọrùn jù, tí ó sì tún lè jẹ́ kí wọ́n jẹ́ èyí tó dára jù fún àyíká.

Iṣẹ́ tó rọrùn:Ẹ̀rọ ìdènà bọ́ọ̀lù náà ń mú kí ìṣípo tí ó rọrùn àti tí ó péye ju àwọn ètò ìgbéjáde mìíràn lọ. Iṣẹ́ dídán yìí dín ìpele ìgbọ̀nsẹ̀ àti ariwo kù nígbà tí a bá ń ṣiṣẹ́ mọ́tò, èyí sì ń mú kí iṣẹ́ rẹ̀ dákẹ́ jẹ́ẹ́ tí ó sì dúró ṣinṣin. Nítorí náà, àwọn mọ́tò wọ̀nyí yẹ fún àwọn ohun èlò tí a nílò láti fi dín ariwo àti ìgbọ̀nsẹ̀ kù.

Pípẹ́ àti Ìgbẹ́kẹ̀lé:A ṣe àwọn mọ́tò ìdènà bọ́ọ̀lù aláwọ̀ 42mm fún agbára àti ìṣẹ́ pípẹ́. Ẹ̀rọ ìdènà bọ́ọ̀lù náà, pẹ̀lú àwọn èròjà tó ga, ń rí i dájú pé iṣẹ́ rẹ̀ ṣeé gbẹ́kẹ̀lé àti pé ó dúró ṣinṣin kódà nígbà tí iṣẹ́ bá ń le koko. Èyí ń mú kí àwọn ohun tí a nílò láti ṣe ìtọ́jú dínkù àti pé ó ń mú kí ètò náà túbọ̀ gbẹ́kẹ̀lé.

Awọn ibeere fun yiyan mọto:

►Ìtọ́sọ́nà ìṣípò/ìgbékalẹ̀

► Awọn ibeere fifuye

► Awọn ibeere fun ọpọlọ

► Awọn ibeere ẹrọ ipari

► Awọn ibeere to peye

► Àwọn ìbéèrè fún ìdáhùn Encoder

► Awọn ibeere fun atunṣe afọwọṣe

► Awọn ibeere Ayika

Idanileko iṣelọpọ